Dewatering Pump Parts For Underground Mining

Mining operators hate delays. You can imagine how mine managers feel about delays in their mining schedules where the root cause is a failure in a submersible pump part.

Sometimes issues can arise with submersible pumps designed for international markets coming up against unique problems created by Australian conditions.

So PumpEng decided to would jump in and modify OEM, mass-produced pump components so that they are better suited to Australian operating conditions.

In the process, we also aimed to help out with the cost of maintenance. PumpEng parts cost, on average, 20% less than OEM parts.

We can help reduce delays because PumpEng parts are 100% interchangeable with the OEM product. Our patented products allow quicker and easier replacement.

Our innovative design improvements mean we are constantly working to improve your pump's performance through improved products and services and more robust design elements.

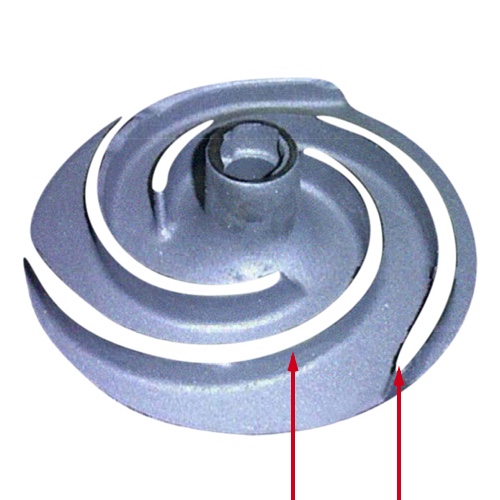

Redesign: Shrouded Impeller

Problem:

If the vane tips are knocked during assembly or should a rock pass into the wet‐end during operation they can break off causing additional consequential damage to the suction cover and diffuser. The other issue occurred when the back of the vanes wear, clearances increase and the opportunity for slippage past the vanes increases thereby decreasing pumping performance.

Solution: PumpEng Impeller

We've improved the design of the impellers. Our impeller tips are protected by a shroud, ensuring no breakage. The shroud ensures fluid doesn’t slip past vanes causing slippage, wear and loss of head.

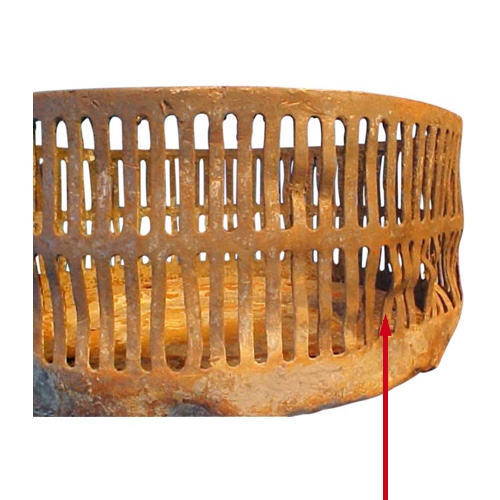

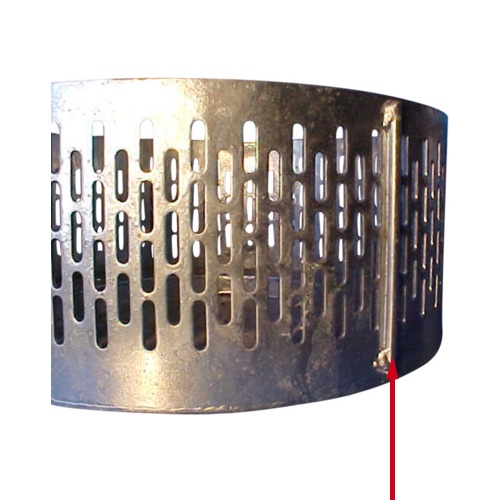

Redesign: Suction Strainer

Problem: The old suction strainer gets damaged and holes open up and allow large rocks to enter wet‐end causing premature failure of impellers or soft components.

Solution: PumpEng Heavy Duty Suction Strainer

PumpEng has designed its strainers with heavier wall thickness material and fitted re‐ enforcement bars.

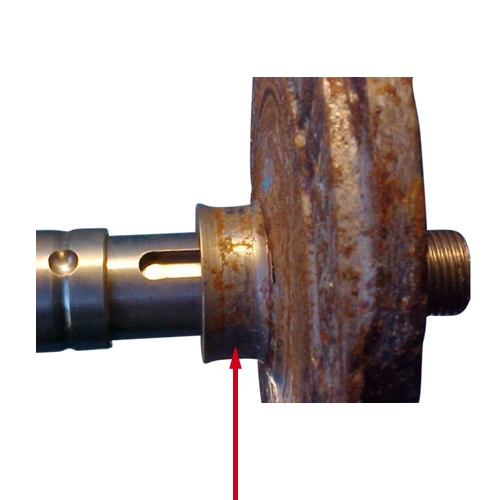

Redesign: Impeller with replaceable neck bush

Problem: Standard impellers have a fixed neck bush which, when worn causes premature replacement of the impeller even though the impeller vanes may be in good condition.

PumpEng Replaceable Neck Brush

PumpEng has designed their impeller with a replaceable neck bush which, when worn, can be replaced at a tenth the cost of a replacement impeller.

Redesign: Outer Casings

Redesign: Side Cable Entry Junction Box

Problem: The standard 8kW design junction box cover incorporates a top entry cable connection which is subject to damage due to operators lifting the pump via the handle and hitting the cable. This is a serious concern particularly being used on 1000v in water.

Redesign: Pump Out Vanes

Problem: The standard design impeller pump-out grooves become blocked with fines quite quickly, thereby allowing fines to build up on the back of the impeller, causing premature wear and failure.

PumpEng Pump Out Vanes

PumpEng has designed their impeller with rear pump out vanes of the type typically used on purpose-designed slurry pumps. These vanes effectively force fines away from the back of the impeller, ensuring wear is kept to a minimum.

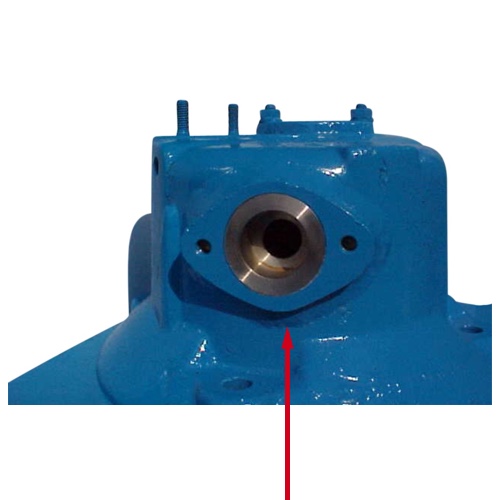

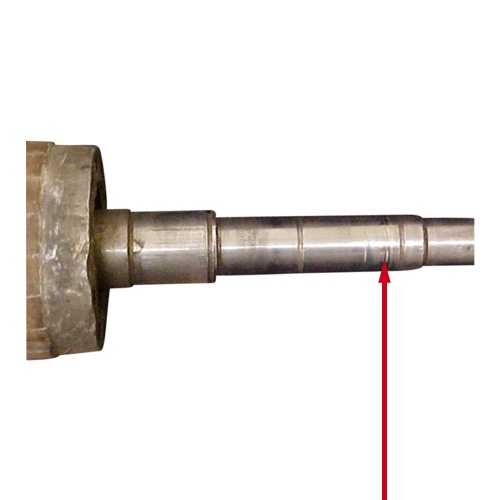

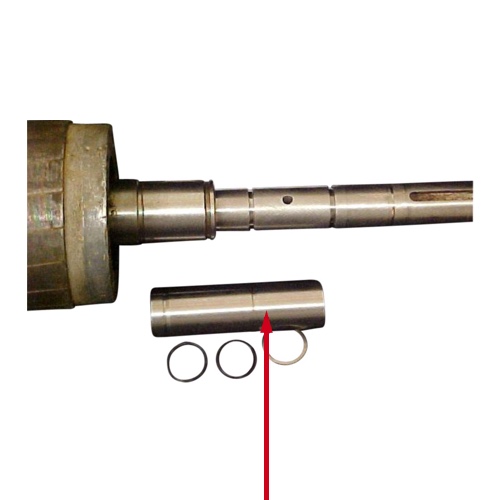

Redesign: Rotor Shaft Sleeve

Problem: Rotor shaft corrodes under the mechanical seal area. In underground conditions this is not uncommon due to low PH water through high salt contents of up to 200,000ppm.

PumpEng Rotor Shaft Sleeve

PumpEng has designed a replaceable shaft sleeve that negates the need for total strip down of the pump and refurbishment of the rotor at a quarter of the approximate cost of reclamation of the rotor seal area.

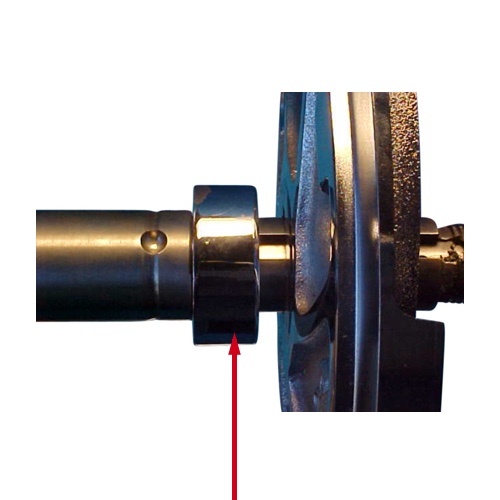

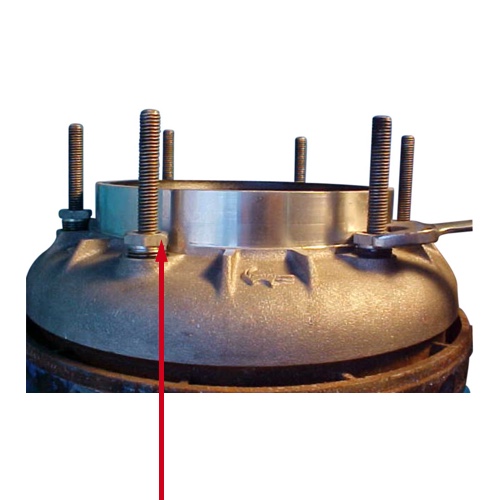

Redesign: Impeller Clearance

Problem: Fitters take up to 30 minutes to set the critical impeller clearances using shims with a standard diffuser.

PumpEng Impeller Clearance Solution

PumpEng patented design shimless diffuser eliminates the need for shims, and all adjustment is done via external setting nuts. A setting tool ensures that a 8kW impeller is set in less than 5 minutes and also means that critical clearances are set each and every time.

Redesign: Bottom Suction Strainer

Problem: Standard design suction strainers become blocked with the new carbon fibre grout re‐enforcement currently being used in some mines. These problems cause premature failures through dry running and necessitates complete strip‐down of the pumps.

PumpEng Bottom Suction Strainer

PumpEng have designed a bottom suction strainer which virtually eliminates this problem. Tests have determined that the fibre re‐enforcement floats on the surface of the water and doesn’t get drawn in on the bottom suction design.

General Redesign Solutions

Redesign: PumpEng components utilise urethane soft components. Urethane is renowned in the mining industry for its wear resistance capabilities in difficult and abrasive applications.

Mechanical Seals

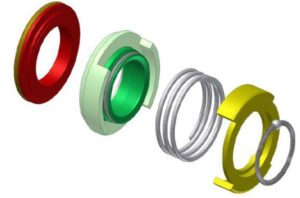

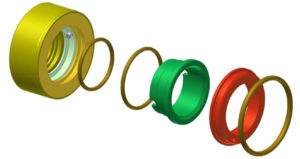

Redesign: 5kw, 8kw and 20kw Upper Seals

Problem: When using hard faces with buna rubber at higher temperatures, original seals required viton rubber to maintain integrity of bond between insert and rubber, causing duplication of stock or potential to use wrong seal in wrong place.

PumpEng 5kw, 8kw and 20kw upper Seals

PumpEng have improved the vulcanisation bond and drive design between the tungsten carbide insert and the rubber seal allowing the buna rubber part to perform in higher operating temperatures without loosing drive.

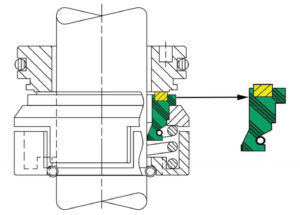

Redesign: Typical 5kW and 8kW Seals

Problem: Removal of stationary seats has been a problem in 5kW and 8kW pumps. In some cases, it is necessary to remove the motor housing to take the stationary seat out.

PumpEng Typical 5kW and 8kW Seals

PumpEng removed the stationary seats that have been a problem in 5kW and 8kW pumps. In some cases, it is necessary to remove the motor housing to take the stationary seat out. PumpEng has made the solid tungsten carbide faces with a special “extraction groove” to allow simple removal of the stationary seat.

Redesign: 20kw Lower Seal

Problem: Original seals have wafer’s of tungsten carbide inserted into a different base material. Distortion takes place between the dis‐similar metals causing premature seal face leakage or the insert comes loose in the holder.

PumpEng 20kw Lower Seal

PumpEng have manufactured both rotary and stationary seats in “solid tungsten carbide”, thus eliminating distortion and potential for inserts to come loose.

PumpEng: The Problem Solver

After years of developing these parts with components manufactured in Australia to suit modern mining conditions where Shotcrete fibre is present in wastewater, we can deliver an efficient part replacement for underground mining operators. Not only that, we can improve the pump's endurance by supplying parts designed to overcome known problems.

If you are interested in a more efficient underground mine dewatering system, speak to us about The PumpEng Way. It is a professional approach to continuous improvement in underground dewatering systems.

Interested in more information about the compatible Raptor® pump?